Author(s) : Martin De Bie

The idea is to create a non-woven homemade piezoresistive material. By using the technique of making cotton paper mixed with graphite powder, i manage to create a piezo resistive material which can easily replace expensive material like Eeonyx. This process is the continuity of an experimentation made with students (Céleste Teikiteetini and Jules Lobgeois) during a workshop that i lead.

To show the capabilities of this material, i integrate it into a simple circuit with led where it would play the role of simple pressure sensor for the swatchbook exchange of the summer camp eTextile 2016.

Ref/inspirations :

Pulp-Based Computing by Marcelo Coelho

http://www.cmarcelo.com/pulp-based-computing/

1- Material

– water

– cotton

– fabric

– paper

– graphite powder

2- prepare paper pulp

Cut cotton, paper and fabric in small piece and put it inside a bowl of water. Leave it like this during 48h at least.

3- Make paper pulp

Use a blender to mix your paste into something homogeneous.

4– Add graphite

Add into your paste graphite, the proportion depends on your tests. In my case, i put 4 big soup spoon for 800g of paste.

Mix it together with a spoon until you get a very black paste.

5- Prepare your graphite pulp

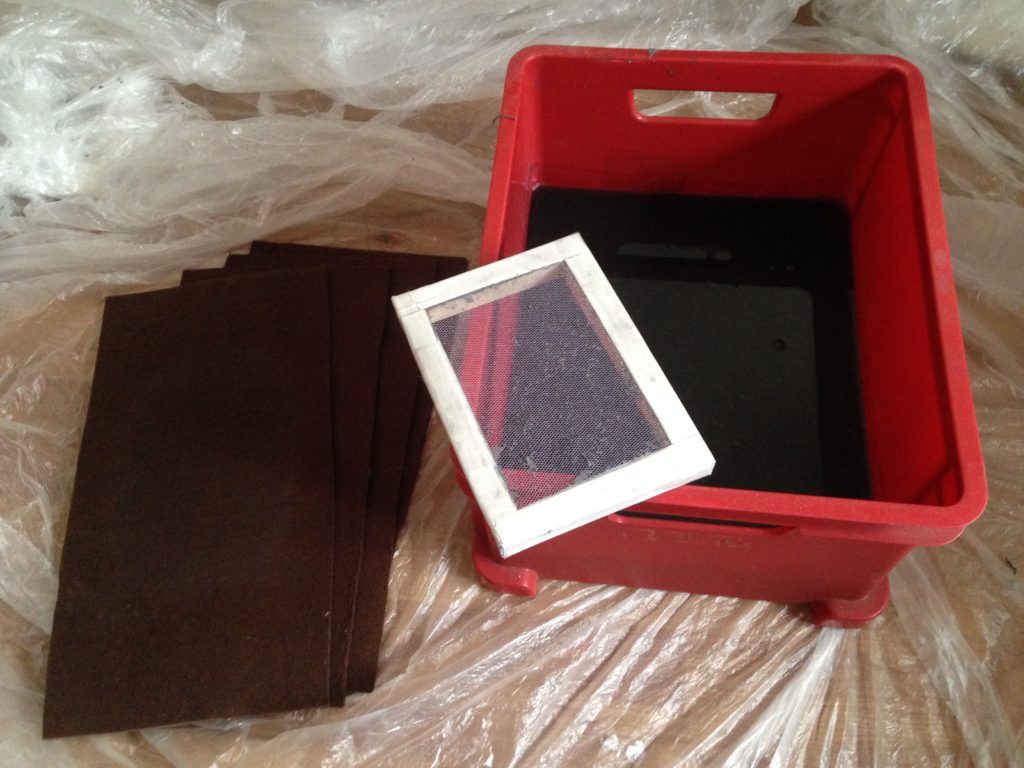

Put your mix inside a big container and add a lot of water. Your mix need to be dilute to make your paper.

I use a frame that i’ve build with regular tulle attached to the wood.

6- Make a sheet of paper

Dip your frame and take it out from the water quickly to catch pulp to create your sheet.

Apply your sheet on a piece of felt to absorb the water and let it dry.

You can try to add together different layers of paper to increase the thickness of the sheet and the resilience of the matter.